4.1 KiB

4.1 KiB

Table of Contents

- 3D Print Meetup Challenges

- 🗓️ October 2025 Challenge: "Is it Glass or Clearly Natural?"

3D Print Meetup Challenges

🗓️ October 2025 Challenge: "Is it Glass or Clearly Natural?"

🎯 Challenge Overview

Experience the clarity of 3D Fuel's "Clearly Natural" filament in this transparency-focused challenge! Participants will attempt to create the clearest possible print, testing the limits of clear filament printing techniques.

📋 Challenge Rules

Materials & Constraints

- Filament: 3D Fuel "Clearly Natural" - Available in two variations:

- PCTG (Polyethylene Terephthalate Glycol)

- PLA (Polylactic Acid)

- Maximum Filament Usage: 250g per entry

- Model Specification: Cylinder - 25mm diameter × 50mm height

- Print Mode: Vase mode (approximately 6 grams of filament)

Competition Categories

- PCTG Division: For prints using Clearly Natural PCTG

- PLA Division: For prints using Clearly Natural PLA

- Overall Winner: Best clarity across both divisions

Judging Criteria

- Clarity & Transparency (40%): How clear and glass-like is the final print?

- Print Quality (30%): Surface finish, layer adhesion, and overall structural integrity

- Technique Innovation (20%): Creative printing techniques to maximize transparency

- Challenge Adherence (10%): Following material constraints and using supplied model

Submission Requirements

- Model Compliance: Cylinder must measure 25mm diameter × 50mm height

- Vase Mode: Must be printed in vase mode (single perimeter wall)

- Weight Verification: Should use approximately 6 grams of filament

- Documentation: Include photos showing transparency (with light sources)

- Settings Documentation: Share printer settings used (layer height, temperature, speed, etc.)

- Process Notes: Brief description of techniques used to achieve clarity

Evaluation Process

- Transparency Test: Prints will be evaluated under controlled lighting conditions

- Comparative Assessment: Side-by-side comparison with actual glass reference

- Community Voting: People's choice award for favorite clear print

- Technical Review: Expert panel assessment of print quality and technique

🏆 Prizes & Recognition

Awards

- PCTG Division Winner: Recognition + prize

- PLA Division Winner: Recognition + prize

- Overall "Glass Master" Winner: Grand prize + recognition

- People's Choice Award: Community favorite

- Innovation Award: Most creative clarity technique

Documentation

- Winner photos for social media sharing

- Video documentation of winning techniques

- Settings and process sharing for community learning

📅 Timeline

- Challenge Announcement: October 1, 2025

- Model Specification Released: October 13, 2025

- Submission Deadline: October 28, 2025

- Judging Period: October 29-30, 2025

- Winner Announcement: October 31, 2025

<EFBFBD> Creating the Cylinder Model

Using Bambu Studio

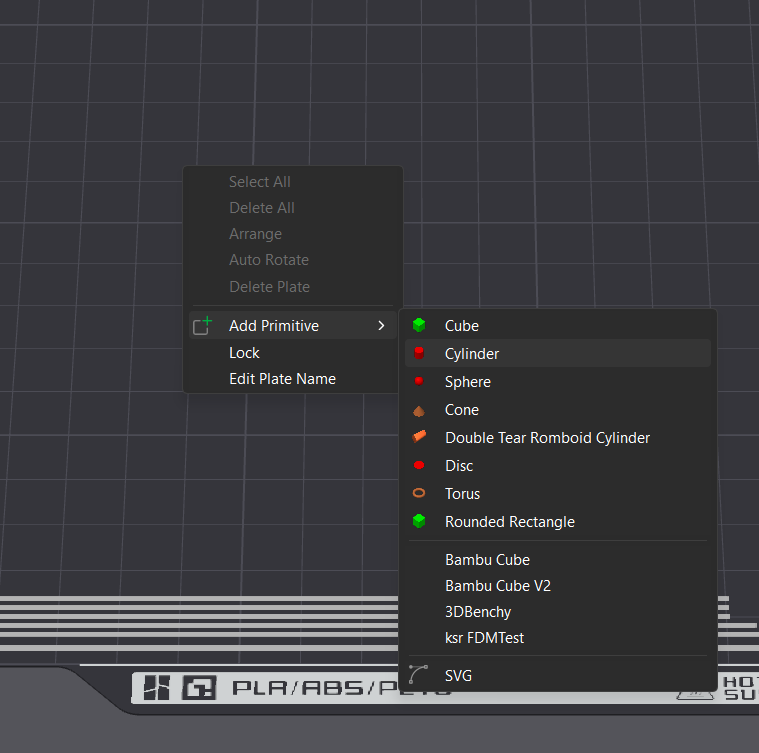

Step 1: Add Primitive

- Open Bambu Studio to a new project

- Right-click on the build plate

- Select "Add Primitive"

- Select "Cylinder"

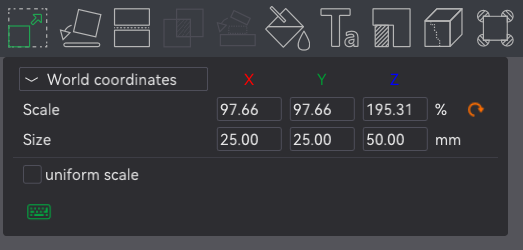

Step 2: Resize the Cylinder

- Click to resize the cylinder

- Uncheck "uniform scale" if checked

- Set X and Y to 25mm

- Set Z to 50mm

Alternative Methods

- Fusion 360: Create cylinder sketch, extrude to 50mm height

- Tinkercad: Use cylinder shape, adjust dimensions

- FreeCAD: Create cylinder with specified dimensions

- Any CAD Software: Simple cylinder 25mm diameter × 50mm height

<EFBFBD>💡 Tips for Success

- Vase Mode Settings: Ensure single perimeter, no infill, no top layers

- Layer Height: Experiment with smaller layer heights (0.1-0.2mm) for better clarity

- Print Speed: Slower speeds in vase mode often improve surface quality

- Temperature Tuning: Optimal temperature is critical for transparency

- Cooling: Proper part cooling helps maintain wall quality in vase mode

- Post-Processing: Light sanding or vapor smoothing can enhance clarity